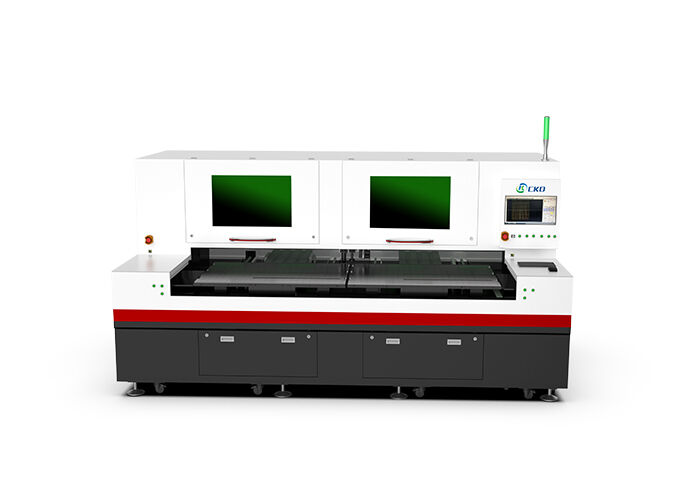

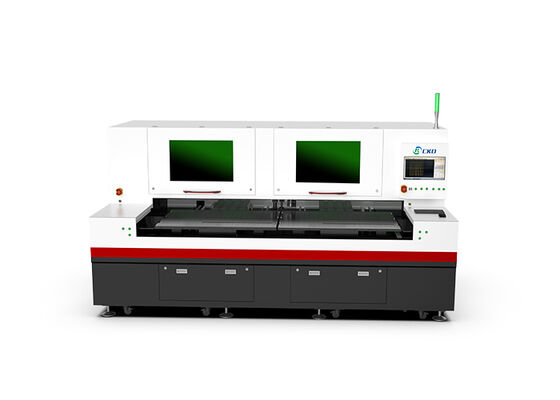

Machine de découpe laser de verre avec paramètres de coupe réglables pour manipuler différents matériaux et épaisseurs de verre à une précision ± 0,01 mm

-

Poids3500 kg

-

Précision de coupe±0,01mm

-

Points de vente clésUltra Fast Picesecond

-

Type de laserPicoseconde infrarouge

-

Épaisseur de coupeJusqu'à 15mm

-

MarqueCKD

-

Largeur de coupe0,03-25 mm

-

Largeur d'impulsion<10ps

-

Consommation d'énergie≤12KW

-

Taille de travail60*80cm

-

Matériel applicableAcrylique, Verre, Papier, Plastique, Cristal

-

softwareCompatibilityAutoCAD, CorelDraw, CAO

-

Fréquence de travail50 Hz/60 Hz

-

Marque de source laserRaycus

-

Méthode de refroidissementRefroidissement par eau

-

Poids de la machine2000 kg

-

Format graphique de soutienPLT, DXF, IA, etc. Il est également possible d'utiliser les données de base.

-

Qualité du faisceauM ^ 2 <1,2

-

Environnement opérationnelEnviron 26 degrés Celsius

-

Efficacité des machines0-500 mm/s

-

Format graphiquePLT / DXF / BMP / JPG / GIF / PNG / TIF

-

Lieu d'origineChine

-

Nom de marqueCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PrixNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Machine de découpe laser de verre avec paramètres de coupe réglables pour manipuler différents matériaux et épaisseurs de verre à une précision ± 0,01 mm

Description du produit:

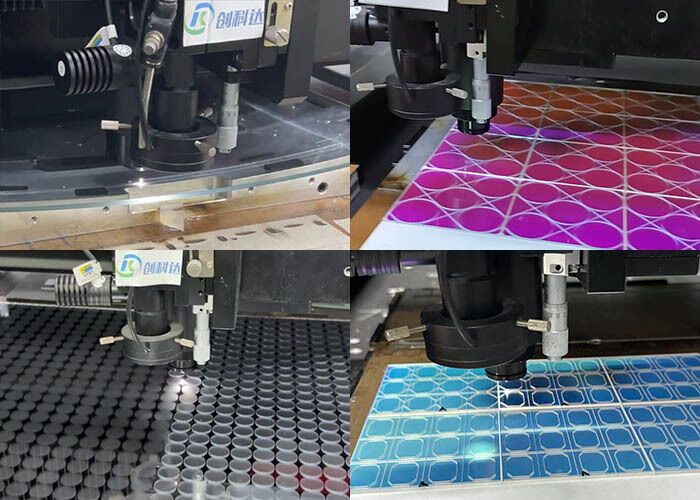

Cet appareil est un appareil de coupe efficace qui utilise des lasers à haute énergie pour couper le verre.La découpe est destinée au traitement de la forme et la découpe assistée par laser CO2 est utilisée pour réaliser la découpe et la découpe du verre. La surface de coupe est lisse, sans écailles, et ne nécessite pas de meulage ou de polissage secondaire.

![]()

![]()

![]()

Paramètres techniques:

| Marque | DTC |

| Type de laser | Picoseconde infrarouge |

| Accélération | 1G |

| Résistance minimale à la coupe | ≤ 5um |

| Précision de coupe | ± 0,01 mm |

| Système de transmission | Rack et Pinion |

| Matériel | Verres |

| Compatibilité avec les systèmes d'automatisation | Prend en charge l'intégration avec les principaux systèmes d'automatisation, y compris les interfaces de robot et les systèmes de chargement/déchargement automatiques. |

| Les avantages | Coupe de forme irrégulière à grande vitesse Qualité de coupe élevée, pas de conique, pas de tache, petit déchiquetage Taux de rendement élevé, faible consommation et économie d'énergie Pas de pollution, pas de poudre et pas d'eaux usées |

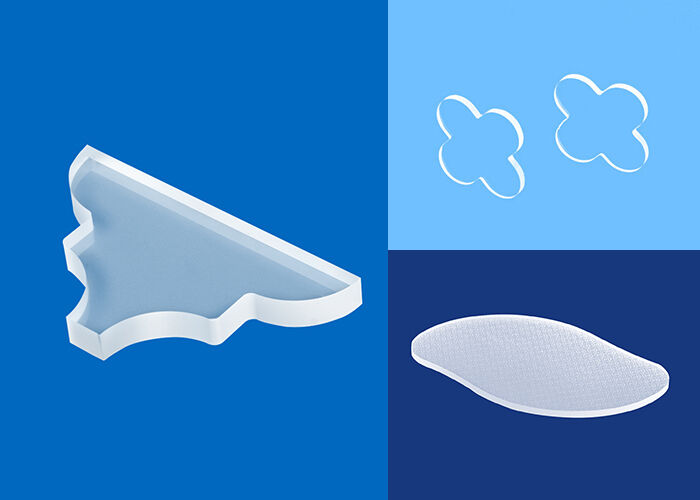

Applications:

Peut traiter "le verre ultra-transparent, le verre blanc ordinaire, le verre silicate à haute teneur en bore, le verre de pierre de quartz", etc., le couvercle de téléphone portable, le couvercle de verre de voiture, le couvercle de verre de caméra, etc., le couvercle de saphir du téléphone portable,couvercle en saphir, bande lumineuse en saphir, verre K9, coupe de film filtrant, coupe par réflecteur, etc.

![]()

![]()

Introduction à l'entreprise:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. a été créée en 2010.C'est un fabricant d'équipements laser ultra rapides et un fournisseur de solutions de fabrication intelligente qui intègre la R & DAprès plus de dix ans de culture et d'accumulation profonde, la société a accumulé plus de 70 brevets, passé la certification CE,1S09001 Certification du système de gestion de la qualité, et la certification du système de gestion de la propriété intellectuelle. C'est une entreprise nationale de haute technologie et une entreprise professionnelle, raffinée, spéciale et innovante de Shenzhen.

La société possède un atelier de tôle, un atelier d'usinage, un atelier d'assemblage et un atelier de développement et de débogage de processus, couvrant la R&D, la production, les tests, la vente et le service après-vente.

Jusqu'à présent, la société dispose d'une solide équipe de R & D qui s'est engagée dans la conception de structures laser et la technologie d'application laser depuis de nombreuses années.la société a réalisé des innovations et des percées dans la technologie des produits dans des domaines tels que la découpe laser ultra rapide, le forage laser, la réparation laser d'écrans TFT-LCD, l'étanchéité et le décapage des plastiques semi-conducteurs, le broyage des diamants, le soudage laser et le marquage laser.Surtout dans le traitement de matériaux durs et fragiles tels que le verre et la céramique, réparation de TFT-LCD, scellement et débonding de plastique semi-conducteur, ainsi que le broyage des diamants et d'autres nouvelles fabrications intelligentes automatisées, nous fournissons aux clients deset des solutions à haut rendement,en apportant des contributions au client par la valeur ajoutée, l'innovation et le développement.

![]()

![]()

![]()

Emballage et expédition

Emballage et expédition du produit pour la machine de découpe au verre laser

Notre machine de découpe au laser est soigneusement emballée pour s'assurer qu'elle arrive en toute sécurité et en parfait état de fonctionnement.Chaque unité est solidement enveloppée de matériaux de protection pour éviter tout dommage pendant le transport.La machine est ensuite placée dans une caisse en bois robuste conçue pour résister aux manipulations difficiles et aux facteurs environnementaux.

Pour plus de sécurité, l'emballage est renforcé par des sangles en acier et des matériaux absorbant les chocs.Tous les composants et accessoires délicats sont emballés individuellement et clairement étiquetés pour une identification facile à la livraison..

Nous offrons plusieurs options d'expédition pour répondre à vos besoins, y compris le fret aérien, le fret maritime et les services de messagerie express.Notre équipe logistique travaille avec des transporteurs fiables pour assurer une livraison rapide et efficace dans le monde entier.Des informations de suivi sont fournies pour tous les envois afin de vous tenir informé tout au long du processus de livraison.

Avant l'expédition, chaque machine de découpe laser de verre est soumise à une inspection et à des tests approfondis pour garantir la qualité et les performances.Des solutions d'emballage sur mesure sont également disponibles sur demande pour répondre à des exigences spécifiques.

Faites-nous confiance pour livrer votre machine à découper le verre au laser en toute sécurité et à temps.

![]()