Machine de découpe au laser de verre de pointe pour des performances de coupe optimales jusqu'à la déchiquetage ≤ 5 μm

-

précision de coupe± 0,01 mm

-

Résistance minimale à la coupe≤ 5 μm

-

Résistance minimale à la coupe≤ 5um

-

Caractéristiques de sécuritéComprend le bouton d'arrêt d'urgence, le couvercle de protection, les fenêtres de sécurité laser et

-

Prise en charge des formats image et texteLa valeur de l'émission est calculée à partir de la valeur de l'émission.

-

Largeur d'impulsionPour les appareils électroniques

-

Voltage, Powe. Je vous en prie.Pour les appareils à commande numérique

-

Épaisseur de coupeVerres ultra-transparents à coupe simple ≤ 19 mm, verres bleus à coupe double ≤ 19 mm

-

ProduitDécoupeuse de laser à verre

-

Matériel à utiliserAcrylique, verre, papier, plastique, cristal

-

Environnement de fonctionnementEnviron 26 degrés Celsius.

-

Le pouvoir50 W/80 W

-

Puissance laser60W/80W

-

Qualité du faisceauM^2 est inférieur à 1.2

-

Poids de la machine2 000 kg

-

Précision de coupeHaute précision

-

type de produitMachine de taille du verre

-

Vitesse0-500mm/s

-

taille de la machinePour les autres types d'équipement

-

Système de transmissionRack et Pinion

-

Zone de travailPour les véhicules à moteur à combustion

-

Système de conduiteHTI

-

Marque de la source laserLes produits suivants:

-

Système de refroidissementRefroidissement par eau

-

Taille de coupe40*50cm*2

-

Environnement de travail<25℃

-

Longueur d'onde du laser1064 nm

-

Accélération1 g

-

Vitesse coupée0-500mm/s

-

Points clés de venteAutomatique

-

Énergie220v/50hz

-

Couverture par longueur d'onde1064 nm

-

Les avantagespetites éclaboussures

-

Méthode de coupeCoupe au laser

-

Taille du travail600*700 mm*2

-

Lieu d'origineLa Chine

-

Nom de marqueCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PrixNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

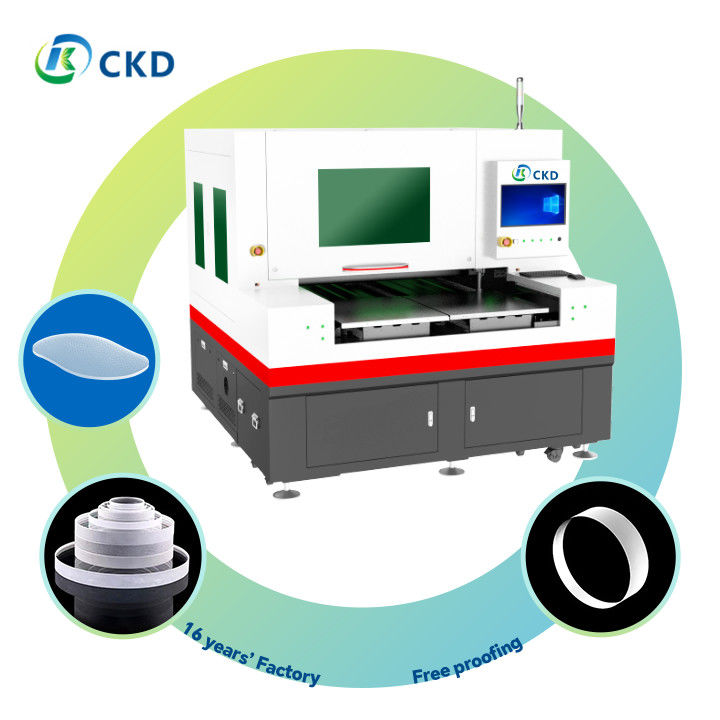

Machine de découpe au laser de verre de pointe pour des performances de coupe optimales jusqu'à la déchiquetage ≤ 5 μm

Description du produit:

La machine de découpe et de fractionnement de verre (tout en un) est un produit de pointe conçu pour répondre à tous vos besoins de coupe de verre.Cette machine de pointe fonctionne avec une précision et une efficacité exceptionnelles., ce qui en fait le choix idéal pour diverses applications, y compris la découpe de vitraux, la découpe laser à fibres et la découpe laser de verre de protection de l'environnement.

L'un des points forts de cette machine est son efficacité énergétique, avec une puissance en veille d'environ 500 W et une consommation moyenne de 2,5 kW pendant les opérations de coupe.Cette machine est non seulement puissante mais aussi respectueuse de l'environnement.Il dispose de modes écologiques qui contribuent à réduire la consommation d'énergie sans compromettre les performances.

En ce qui concerne les niveaux de bruit, la machine de découpe et de fractionnement de verre est conçue pour fonctionner silencieusement.Cette machine est adaptée aux environnements où un faible niveau de bruit est crucial.Que vous travailliez dans un atelier, un atelier ou dans n'importe quel autre environnement, vous pouvez compter sur cette machine pour réaliser des coupes précises sans causer de perturbation.

Équipée d'une fréquence d'impulsion allant de 1 Hz à 1000 kHz, cette machine offre des capacités de coupe polyvalentes pour répondre à diverses exigences.Que vous ayez besoin de faire des coupes complexes ou de trancher à grande vitesseLa régulation de la fréquence d'impulsion vous permet d'ajuster la vitesse de coupe en fonction des exigences spécifiques de votre projet.

Une autre caractéristique remarquable de cette machine est sa longueur d'onde de 1064 nm.ce qui le rend idéal pour un large éventail d'applications de coupe de verreQue vous travailliez sur des matériaux en verre minces ou épais, cette machine offre des performances constantes et des coupes précises à chaque fois.

Caractéristiques:

- Nom du produit: Machine à découper le verre au laser

- Nom: machine de découpe et de fractionnement de verre (tout en un)

- Source laser de scission: RFC02 (CO2 à radiofréquence) - RFC02 10,6 μm 150 W (options: 250 W / 350 W) - 150 W ((250 W / 350 W) refroidissement par eau de 1 à 100 kHz

- Industrie concernée:

- L'industrie du verre: verre optique, verre K9 et verre ultrafin

- Industrie des articles ménagers: verre à haute teneur en borosilicate, verre au quartz, verre pour articles sanitaires

- L'industrie automobile: verre automobile, pare-brise automobile, etc.

- Nouvelle énergie: le verre photovoltaïque

- Appareils électroménagers: Verres pour appareils électroménagers, panneaux lumineux

- Immobilier: décoration architecturale, verre de salle de bain, etc.

- Type de laser: Picoseconde infrarouge

- Accélération: 1G

Applications:

Occasions et scénarios d'application du produit pour la machine à découper le verre au laser CKD:

La machine de découpe laser de verre CKD est un outil polyvalent et efficace qui peut être utilisé dans divers scénarios et occasions.

- Coupe de verre irrégulier: La machine de découpe de verre au laser CKD est idéale pour couper des formes et des motifs irréguliers sur le verre avec précision et précision.Cette machine peut gérer la tâche efficacement..

- Machine de découpe laser à fibre: La machine de découpe laser à verre CKD utilise une technologie laser à fibre avancée pour fournir des résultats de coupe rapides et précis.Il est adapté pour couper une large gamme de matériaux en verre avec facilité.

- Machine de découpe de vitraux: Avec ses capacités de découpe de haute précision, la machine de découpe de vitraux au laser CKD est parfaite pour couper des pièces de vitraux à des fins artistiques et décoratives.Il assure des coupes propres et lisses, préservant l'intégrité du verre.

Les spécifications:

- Nom de marque: CKD

- Numéro de modèle: CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE et plus

- Lieu d'origine: Chine

- Certification suivante: ISO, CE

- Quantité minimale de commande: 1

- Prix: négocié

- Détails de l'emballage: Emballage sous vide en bois

- Délai de livraison: 25 à 45 jours

- Conditions de paiement: L/C, T/T

- Capacité d'approvisionnement: 60 ensembles par mois

- Accélération: 1G

- Moteur d'entraînement: moteur linéaire XY + échelle de grille optique

- Largeur de coupe: 0,03-25 mm

- Voltage, puissance: < 8 kW, AC220V

Personnalisation:

Services de personnalisation de produits:

Nom de marque: CKD

Le numéro de modèle est le suivant: CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE,Les données sont fournies par les autorités compétentes de l'État membre.Les résultats de l'analyse de l'efficacité de l'utilisation de la méthode de dépistage de l'infection par le médicament doivent être présentés dans un dossier de dépistage.

Lieu d'origine: Chine

Certification suivante:

Quantité minimale de commande: 1

Prix: négocié

Détails de l'emballage: Emballage sous vide en bois

Délai de livraison: 25 à 45 jours

Conditions de paiement: L/C, T/T

Capacité d'approvisionnement: 60 ensembles par mois

Type de laser: Picoseconde infrarouge

Fréquence d'impulsion: 1 à 100 kHz

Caractéristiques de sécurité: Comprend le bouton d'arrêt d'urgence, le couvercle de protection, les fenêtres de sécurité laser et l'arrêt automatique lorsque le couvercle est ouvert pour un fonctionnement sûr.

Nom: machine de découpe et de fractionnement de verre (tout en un)

Méthode de refroidissement de la source laser par fractionnement: refroidissement par eau

Mots clés: Coupe de verre irrégulier, Machine de coupe de verre à table unique, Machine de coupe de verre teinté

Assistance et services:

Le support technique du produit et les services pour la machine à découper le verre au laser comprennent:

- Conseils d'installation initiale et aide à l'installation

- Formations pour une utilisation efficace de la machine

- Assistance au dépannage pour tout problème technique

- Recommandations d'entretien régulières pour assurer une performance optimale

- mises à jour et améliorations de logiciels pour améliorer les fonctionnalités

Emballage et expédition

Emballage du produit:

La machine à découper le verre au laser est soigneusement emballée dans une caisse en bois solide pour assurer sa sécurité pendant le transport.La machine est fermement fixée à l'intérieur de la caisse en utilisant un rembourrage en mousse et des matériaux de protection supplémentaires pour éviter tout dommageL'emballage est conçu pour résister à la manipulation brutale et à l'expédition longue distance.

Pour la navigation:

Une fois la machine à découper le verre au laser emballée, elle sera expédiée par une entreprise de logistique réputée ayant de l'expérience dans la manipulation de machines délicates.Le processus d'expédition sera suivi pour s'assurer que la machine atteint sa destination en toute sécurité et à tempsLes clients recevront un numéro de suivi pour surveiller l'état de leur envoi.